The service of 240 volts works on hard devices such as ovens, air conditioners, water heaters and electric dryers. If something wrong occurs in that painting, this may cause these systems to fail, destroy devices, or even lead to electrical risks.

“This is why you should test the painting to confirm that every 240 -volt boycott provides the appropriate effort,” says Daniel Vasilvsky, director of Bright Force Electrical. “The eclipse will weaken or fail over time, and when they do it, they may not provide 240 volts.”

It is also important to test the 240V circuit bodies to ensure that all wires that enter individual fractures did not become loose or broken. “It is also good to look at it and make sure that there are no loose wires that can be curved or spark in the painting,” says Tod Tribe, a JustansWer home expert.

Here is what to know about the 240V circuit cutting test.

What are you looking for in the brushing box?

Unless your home is very old and the electrical service is never updated, it contains 240 services from the street and to the main electrical panel as well. While you are in that, take this opportunity to get to know the vampire energy To get the power of willingness that can make many your devices operate 24 hours a day. (Also, explore what modern home buyers need New home appliances))

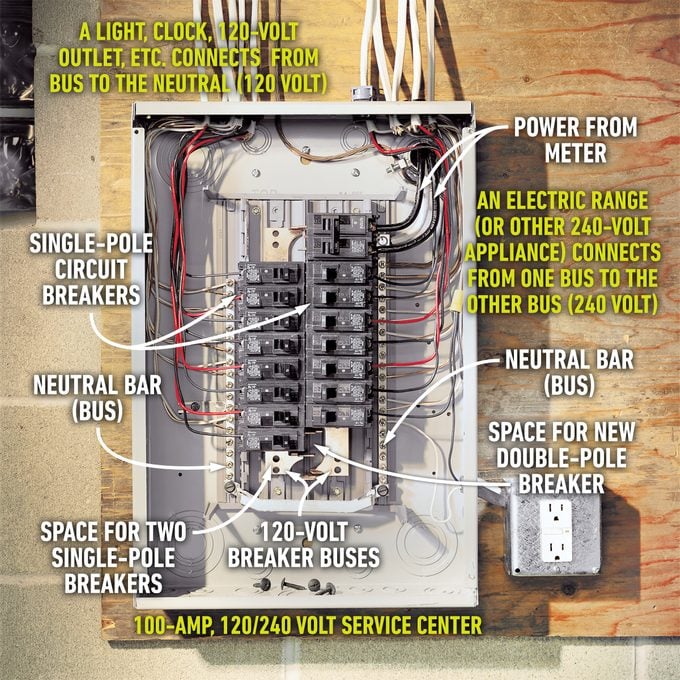

Each main electrical plate has two wires 120 volts and one neutral wire that works on it from the utility company. Each wire runs a “bus” (a copper vertical leg) inside the main service panel. For this reason, you usually see two pillars of circuit breakers (or valves) when the service plate is opened.

Common circles with 120 volts that run everything from the lava lamp to a vacuum cleaner through one of these two busies. Standard circuit breakers 15 or 20-AP work by cutting on a bus. After that, the hot feeding wire (red or black) is installed on the circuit breaker, while the neutral (white) wire and the naked copper wire are installed on the common neutral tape.

The way you get a simple 240 -volt circuit. The “double” circuit breaker is cut in both 120 buses at the same time, and thus the voltage is doubled to the circle. For this reason, these circles contain two hot, neutral wires, and land in its 240 -volt outlet to carry electricity on the device.

Do you have enough amps in the service panel for a new 240 -volt service?

Service panels are classified for the maximum amps they can provide. For example, the 60-AP board in an older house, for example, can handle up to 60 amps of current to the house. The plate should be large enough to deal with the current electrical demand for the home in addition to the new device without exceeding the classification of the plate. (The standard electrical range that does not have storytelling needs 40 amps.) If this discovery is more complicated than just calculating the electrical load of the circuit sectors already in the plate.

The electric you use to install the new circle will help you determine whether the plate is up to the task. Most home electrical plates have a lot of energy for additional devices, but if you have to increase the ability, there are solutions. Most likely, if you have enough space for the circles, you will not have a problem adding the domain circle, especially if you do not have any energy -related devices over 240 volts such as air conditioners, electric water heaters or dryers. Here are some ideas to cover an electric plate.

The skilled family

The skilled family

Is there a physical space in the service panel for another double -pole crusher 240 volts?

Finally, there should be two spaces in the plate for two additional proxies for the circles. If the available spaces are not directly stacked on top of each other, the existing fractures can be pulled and re -inserted into new locations to provide this arrangement.

If you have an old panel that contains valves instead of fractures, or if the circuit breaker plate is already full, electricity can add a sub -group to deal with the additional 240 volt circuit. SubPanel is a small electric plate that is fed from the main plate to create distances for more circuits. Adding a relatively inexpensive sub -travel, depending on the amount of work that must be done and the status of your service plate.

Perhaps it is not worth the investment sub -group if you have a fuse plate. It would be better to upgrade the main main electrical panel to the modern circuit breaker plate with a large space for additional circuits. Placing a larger high -capacity plate may be the highest cost of the sub -plate several times. It may also require the improvement of the electrical system for the house to match the requirements of local or national electric code, which is a large additional account.

Instructions

What are the tools required to test the Breaker 240 volt panel?

The most important tool is the digital Multimter scale (DMM), which can measure voltage, current and resistance.

“On a 240 -volt board, the multiple scale determines whether the crushing or circle receives the right effort,” says Vasilevski. “It works by measuring the electrical capabilities between two points and gives you an accurate reading.”

Vasilevski also recommends the use of an unconnected voltage test, which detects the presence of live voltage by sensing the electric field around the conductor. “It is fast and easy to use and is an important first step when working near Breaker to confirm whether the system is direct,” he says.

Besides these tools, you will also need an isolated screwdriver, isolated gloves, safety glasses and a manual lamp. The thermal scanner, also known as FLIR, can be a great help.

“Care and extreme caution should be practiced when removing the cap from the circuit breaker plate, testing the voltage to the double pole, fractures and width,” says Trip.

What are the signs of bad crushers 240 volts?

One of the most obvious signs is when the crusher is repeated again. Others include unexplained voltage, no effort, stumbling without load, difficult to run and turn off sponges, increased or escalating, lighting and visible damage.

“If you see a color, a melted appearance, or even a burning smell near the painting, this is a red sign,” says Vasilevski. “These signs indicate that the crusher has increased or emitted, which poses a serious danger to the fire.”

“When the crusher is not reset as soon as it is stumbled, deported immediately or refuses to reset, it can also indicate a bad cutter,” says Docia Boylen, the owner of Golden.

About experts

Next: Check out the home owner’s guide to AC valve box.

Ⓘ