A new technology platform that enhances the performance and life of electric vehicle batteries.

Lithium batteries offer the highest energy density of any battery type. Lithium batteries can store more energy in a smaller, lightweight package than any other type of battery. As a result, lithium-based batteries are the preferred battery type for all types of electric vehicles. Unfortunately, lithium batteries have several downsides. They can experience thermal runaway if they are damaged, under very high loads, overcharged, or exposed to high temperatures. Thermal runaway can generate enough heat to ignite the electrolyte and cause a fire or explosion in the battery pack. Such conditions can seriously damage the battery pack and the electric vehicle and may endanger the occupants.

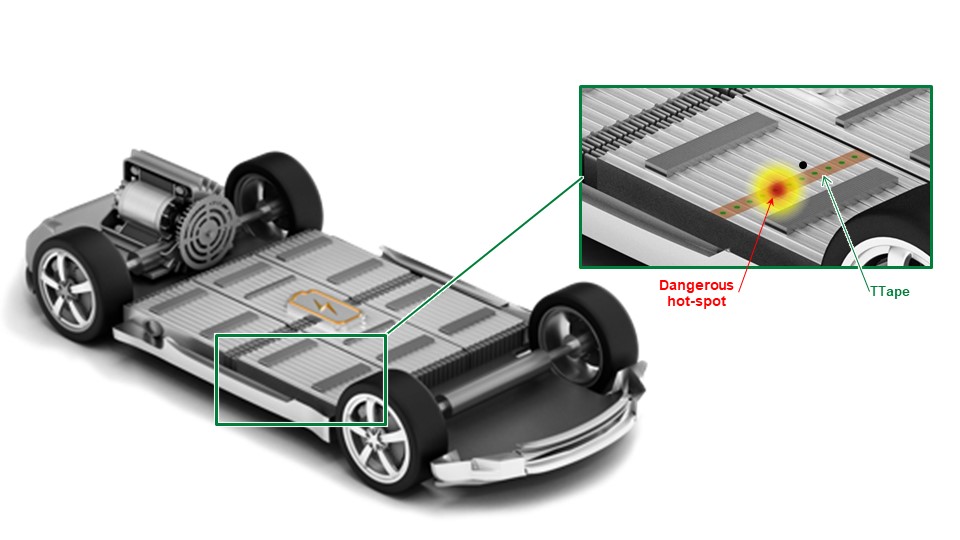

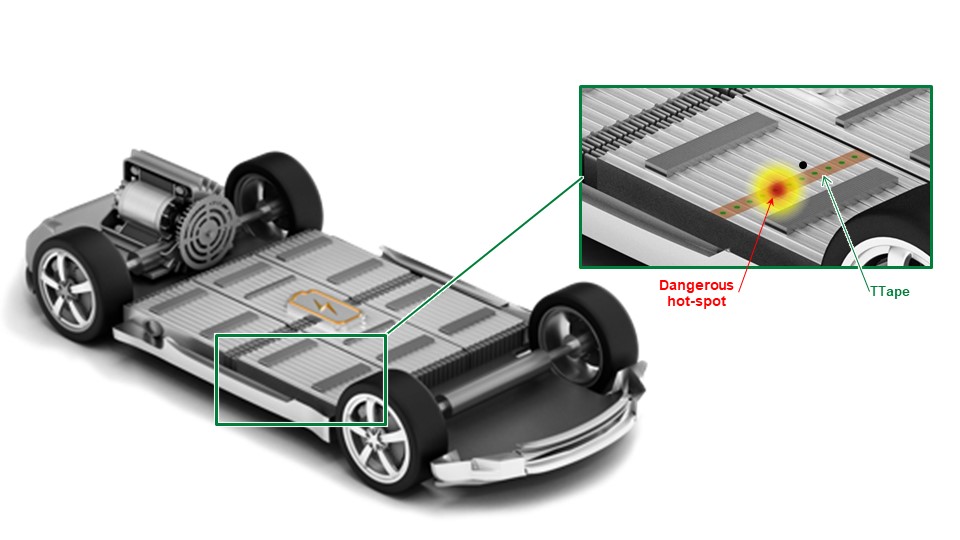

A new technology is now available that mitigates the risk of battery overheating. Littelfuse’s latest technology, the TTape™ distributed temperature monitor, enables early detection of localized battery cell overheating. The innovative platform helps extend battery life and enhance the safety of battery installations. TTape is a strip of tape with multiple closely spaced temperature indicators. Unlike separate thermistors, TTape adheres to the battery cells and conforms to the shape of the cells, enabling high-density monitoring of locations on the battery pack. The temperature sensors quickly detect a hot spot in the cell, preventing battery overheating. With individual thermistors whose size limits the number of detection locations and prevents tight spacing, a hot spot in a battery cell that is not near a thermistor location can rise to a dangerous level. TTape solves the problem of not being able to quickly detect hot spots in a battery cell.

This article introduces the reader to the benefits of the TTape distributed temperature monitor and explains the product details. In addition, a sample circuit is shown for use in the protection scheme. Design engineers will find that TTape is an excellent and simplified component for ensuring maximum life and safe operation of lithium-ion batteries.

TTape Description

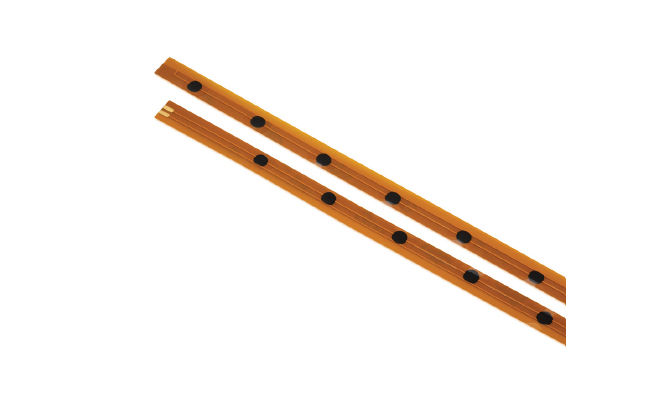

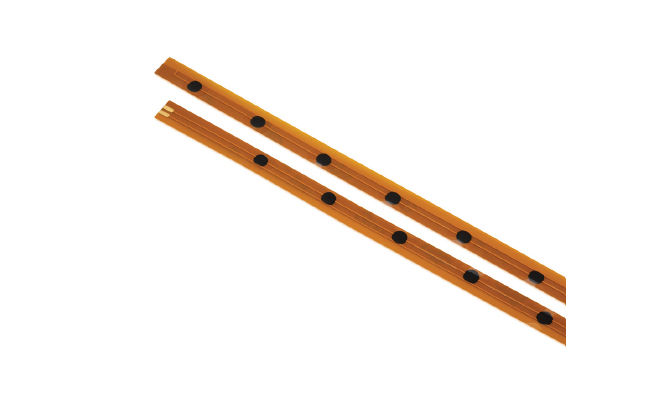

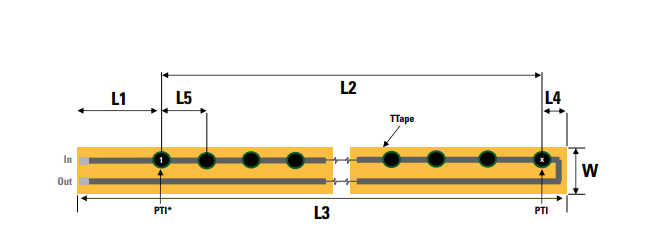

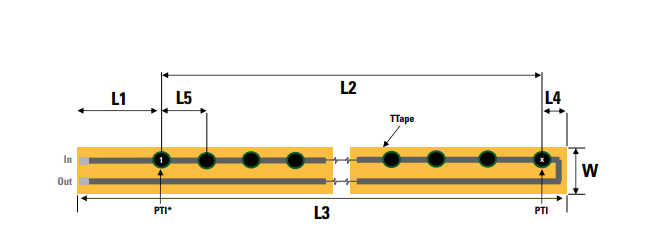

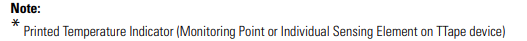

TTape is a thin, flexible strip of closely spaced printed temperature indicators for precise temperature monitoring. It is less than 500 microns thick, allowing it to conform to any battery pack shape. Figure 1 shows TTape with printed temperature indicators (PTIs).

Printed temperature indicators are small dots of polymer material with a positive temperature coefficient. The temperature indicators are connected in series. When the temperature indicator detects a temperature above a threshold level, its resistance increases by a factor of more than 1000.

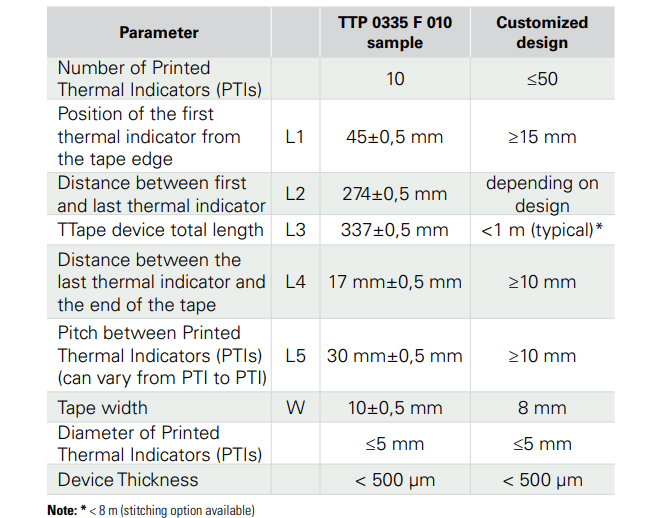

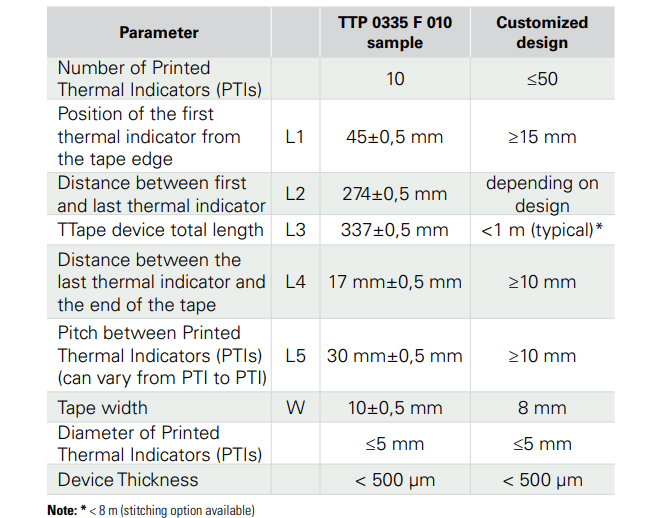

Figure 2 shows the dimensional details of the TTape distributed temperature monitor. The temperature sensors can be placed approximately 10 mm apart. The TTape has narrow width options of either 8 mm or 10 mm and a standard length of 337 mm. Custom designs can be up to one meter long. Pressure sensitive adhesives bond the TTape to a surface. The adhesive allows it to adhere to metal, polyamide, polyethylene terephthalate and polyimide surfaces.

The standard 337 mm tape length includes ten printed temperature indicators. Custom designs can consist of up to 50 printed temperature indicators. The printed temperature indicators have a maximum diameter of 5 mm with a standard spacing of 30 mm. The narrow spacing between the printed temperature indicators allows for increased spatial resolution for monitoring the temperature of all cells in a battery pack. Separate temperature sensors cannot achieve such precise monitoring of all individual battery cells. Furthermore, with a thickness of less than 500 μm, TTape can conform to the irregular surface of the battery pack and be in direct contact with individual battery pack cells.

TTape connects to an electronic circuit through a two-wire solder pad interface. Figures 1 and 2 show the solder pads, and Figure 2 shows their function.

The TTape has a trip temperature setpoint of 58 ± 3°C for early detection of overheating before the battery cell reaches a dangerous temperature level. Lithium-ion batteries and other battery chemistries can be charged and discharged at temperatures below 60°C before typical battery management circuits take action. The battery management system will cut off the load or charging power to the battery pack when a temperature above 60°C is detected. In general, the 58°C setpoint tolerates battery pack temperature fluctuations that occur when the battery pack is under load or being recharged. The printed thermal indicators have a response time of less than one second. If the battery pack temperature exceeds the nominal 58°C for more than one second, the TTape temperature monitor will respond.

To avoid rapid on-off cycles near the threshold temperature, TTape PTI material features a hysteresis property that prevents corrosion of critical system components and avoids false alarms. This design approach ensures that the system only responds when there is a true overheating condition, contributing to the safety and durability of the battery pack.

Implementation of the circuit

The TTape operates in TTL-1, 5V, or 3.3V logic circuits. Figure 3 shows a recommended circuit configuration for use with the TTape display. VT is logically high when the TTape’s printed thermal indicators detect a temperature above 58°C and switch to a high resistance. VT is logically low when the temperature is below 58°C or if the temperature exceeds a threshold temperature and drops below 42°C. The printed thermal indicators exhibit a hysteresis effect of about 16°C once the threshold temperature is exceeded. The right side of Figure 3 shows the hysteresis curve for the TTape.

The logic circuit is a simple circuit using a recommended RP value of 200 KΩ. The VT can provide a signal to the A/D converter in a microcontroller. When the TTape does not detect a battery hotspot, the 5V circuit draws about 25 μA to consume only 125 μW. The TTape only needs one A/D input line on the microcontroller to transmit the temperature status of the battery cells. The microcontroller can either be part of the battery management system or an interface to it.

Compared to temperature monitoring using a separate thermistor

With only 30mm of distance between the printed temperature-indicating sensors and a thin adhesive tape form factor that can conform to any surface, TTape can detect a battery cell temperature rise before a separate sensor can unless the temperature rise is directly below the separate sensor. Figure 4 illustrates this situation. If the thermistor is one cell away from a very hot cell, it can take more than two minutes for the thermistor to respond to the temperature rise. With PTIs on each cell, the response is less than one second.

Unlike the NTC sensor, the TTape temperature monitoring platform does not require calibration because it is essentially a dual-state device. Additionally, the electronics that process the TTape sensors do not require a temperature conversion calibration table.

As a conformal tape, TTape takes up minimal space on the battery pack. TTape allows for easy installation and allows monitoring of any battery pack structure. Figure 5 shows an example of installing TTape monitoring tape on a battery pack.

High density monitoring to enhance safety

The TTape temperature monitoring platform provides designers with the unique ability to monitor temperature in an extremely compact manner for each cell group in an EV battery. High-density monitoring reduces premature aging by detecting and preventing temperature spikes on individual cells or groups of cells. This low-cost, minimal-space solution provides enhanced safety and extended battery cell life. Furthermore, the TTape monitor is AEC-Q200 qualified for use in automotive vehicles.

For more information about the TTape™ Distributed Temperature Monitoring Platform including installation details and circuit implementation, see the TTape™ Distributed Temperature Monitoring Application Note.

For technical assistance, visit the TTape product page and contact Littelfuse at www.littelfuse.com.