Electric vehicles are a green energy solution that paves the way for a pollution-free future. At the heart of modern electric vehicles is the lithium-ion battery, which poses significant challenges due to its sensitivity to temperature changes.

This article explores current battery thermal management systems (BTMS), evaluates their practical applications and design considerations to ensure thermal safety, and explores international market potential.

The article provides an in-depth analysis of thermal stability, addressing critical issues such as:

Given these challenges, improving highway traffic management is critical to the adoption of electric vehicles.

Effective thermal management not only extends battery life, but also enhances overall safety.

In the industry, electric vehicle batteries are considered to have reached the end of their life once they have lost 20% of capacity or increased internal resistance by 30%. Engineers rely on active and passive battery management systems to combat overheating and ensure optimal performance.

How can we ensure the safety of the battery pack of the hybrid and all-electric vehicle?

Ensuring the safety of all-electric and hybrid vehicle battery packs is of paramount importance, especially since consumer confidence depends on the reliability of these systems. Lithium-ion (Li-ion) batteries, the most widely used type, have faced criticism for their instability and potential fire risk.

Lithium-ion cells use volatile organic solvents, such as ethylene carbonate and methyl ethyl carbonate, as electrolytes.

To address these concerns, standards have been developed that address heat generation from rechargeable energy storage systems (RESS), specific crash test requirements, and short circuit protection.

However, due to the wide variety of product designs, no single standard can cover all aspects of safety, leading to potential unforeseen problems.

Thermal management of lithium-ion batteries is not just a theoretical issue, but has been extensively researched and validated. Here are some key findings:

Drake et al. (2015) conducted theoretical and experimental investigations on the effect of temperature on the charge and discharge rates of lithium-ion batteries, and revealed that large heat generation negatively affects battery performance.Zhang et al. (2017) addressed the challenges associated with fast-charging lithium-ion batteries, identifying high temperatures as a major problem. Several other researchers have echoed these findings, emphasizing the critical importance of thermal regulation in maintaining battery efficiency and longevity.Rodriguez-Martinez et al. (2014) found that prismatic pocket cells provide better thermal management due to their large surface area, which helps in heat dissipation and is cost effective.

The need for effective thermal management systems in electric vehicles is clear. By improving these systems, we can significantly improve battery life and safety, making electric vehicles a more reliable and attractive option for consumers.

Thermal stability of BTMS batteries

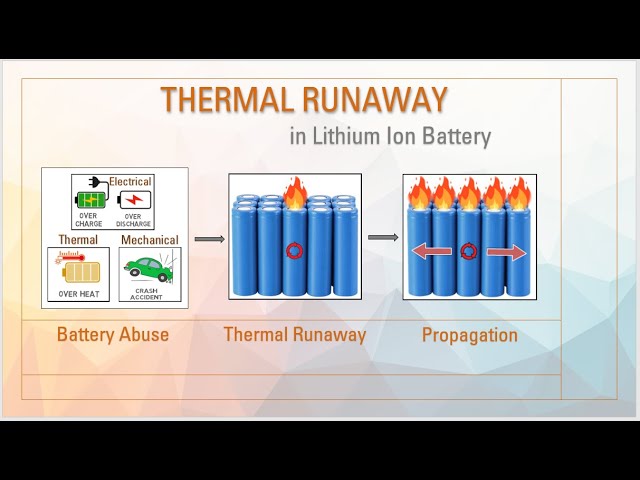

Thermal runaway occurs when a battery generates more heat than it can dissipate, which can have catastrophic results. Mechanical, electrochemical, or thermal failures can cause this to happen. Researchers agree that mechanical mishandling of lithium-ion batteries, without proper safety measures, can lead to thermal runaway.

Thermal runaway occurs when a battery generates more heat than it can dissipate, which can have catastrophic results. Mechanical, electrochemical, or thermal failures can cause this to happen. Researchers agree that mechanical mishandling of lithium-ion batteries, without proper safety measures, can lead to thermal runaway.

Electrical faults, such as short circuits and overcharging, also contribute to increased TR by increasing current flow and power dissipation, causing the battery to overheat.

As temperatures rise, electrolyte oxidation can cause the battery to swell, exacerbating the problem. Thermal failures caused by loose cell packaging or increased internal resistance can also cause TR. Effective heat dissipation can stop internal exothermic reactions, but if the cathode reacts and the separator melts, a voltage drop occurs, making TR inevitable.

When temperatures rise above 60°C – 100°C, the electrolyte reduction process accelerates, resulting in temperatures increasing to 160°C – 170°C.

A high-profile incident involving a thermal leak occurred on a Boeing 787 Dreamliner. NASA’s Engineering and Safety Center addressed the safety concerns and recommended that manufacturers design batteries to prevent such catastrophic events.

The effect of temperature fluctuations on the performance of lithium-ion batteries

Temperature changes can have a significant impact on the performance of lithium-ion batteries, especially in cold conditions. When temperatures drop, the chemical stability of these batteries can decrease, reducing their power and energy capacity by up to 40%.

This is due to factors such as the design and shape of the battery and the effectiveness of the electrolyte solution in cold weather. Studies have shown that pocket-type batteries lose capacity faster as temperatures rise.

For example, its discharge capacity at 25°C is higher than its capacity at 0°C or 45°C.

Battery Thermal Management Strategies

To manage battery temperatures, a thermoelectric model can be used to study how heat is distributed in cylindrical 18650 battery cells.

This model shows that the temperature rises more during the discharge cycle than during the charge cycle, although this difference diminishes with higher current rates (C rate).

The way a battery heats up is related to changes in entropy and the applied current. A detailed analysis found that high current flow can suddenly stop the discharging or charging process, making the battery more susceptible to overheating and possibly thermal runaway during discharge.

Advanced cooling technologies and configurations to improve cooling management system

Research using neural networks has shown that higher discharge rates increase the surface temperature of batteries. Key factors in effective battery cooling include maximum temperature, space utilization, and energy efficiency. Optimal cooling performance is achieved when the airflow inlet and outlet are placed at the top of the battery pack.

However, the cooling efficiency decreases as the number of batteries increases horizontally.

Studies on tubular-shell battery packs have shown that baffles improve fluid contact and heat transfer by altering the air-to-fluid flow.

For convective cooling, the arrangement of the lithium-ion batteries is critical. In stepped arrays, the highest temperature increase is proportional to the longitudinal separation at a given airflow rate, while in stacked arrays, the opposite is true. In both configurations, increasing the transverse separation increases the battery temperature.

Various strategies for BTMS have been reviewed, including phase change materials (PCM), phase change fluids, flexible phase change materials, hybrid cooling, air-liquid cooling, and heat pipe-based cooling. The flammability of organic phase change materials and the stability of inorganic phase change materials are important for improving BTMS.

Yu et al. (2021) explored a hybrid cooling approach for lithium-ion battery packs, by combining micro-heat pipes, forced air convection, and intermittent water spray.

Their global sensitivity analysis found that thermal conductivity, PCM layer thickness, heat pipe length, and water inlet velocity significantly affect the maximum battery pack temperature and temperature distribution.

Authors’ conclusion

Effective battery thermal management systems (BTMS) are essential for the safe and efficient operation of lithium-ion batteries in electric vehicles (EVs).

This article highlights the critical challenges posed by temperature changes, including thermal runaway and the effect of subzero temperatures on battery performance.

We can greatly improve battery safety and longevity by exploring advanced cooling technologies and configurations, such as phase change materials and hybrid cooling systems. Improving battery management systems will enhance battery life and make electric vehicles more reliable and attractive to consumers, ensuring a sustainable and pollution-free future.